Blog

2025 Top Trends in Plastic Masterbatch and Its Impact on the Industry

The global plastics industry is undergoing a transformative phase, with "plastic masterbatch" leading the charge in innovation and sustainability. As we approach 2025, several key trends are emerging that are set to shape the future landscape of this vital sector. Plastic masterbatch, a concentrated mixture of additives and pigments encapsulated in a carrier resin, plays a crucial role in enhancing plastic products' performance and aesthetics. This article explores the top trends influencing plastic masterbatch and how these developments will impact manufacturing processes, market demand, and environmental considerations.

One significant trend is the growing emphasis on sustainability and eco-friendly solutions within the plastic masterbatch industry. As manufacturers and consumers alike become more environmentally conscious, the shift towards biodegradable and recyclable materials is becoming paramount. Additionally, technological innovations in the production of plastic masterbatch promise more efficient and cost-effective solutions, ensuring that businesses can meet evolving market demands while promoting sustainability. Understanding these trends will not only enable companies to remain competitive but will also pave the way for a more responsible approach to plastic production in the years to come.

Emerging Innovations in Plastic Masterbatch for 2025

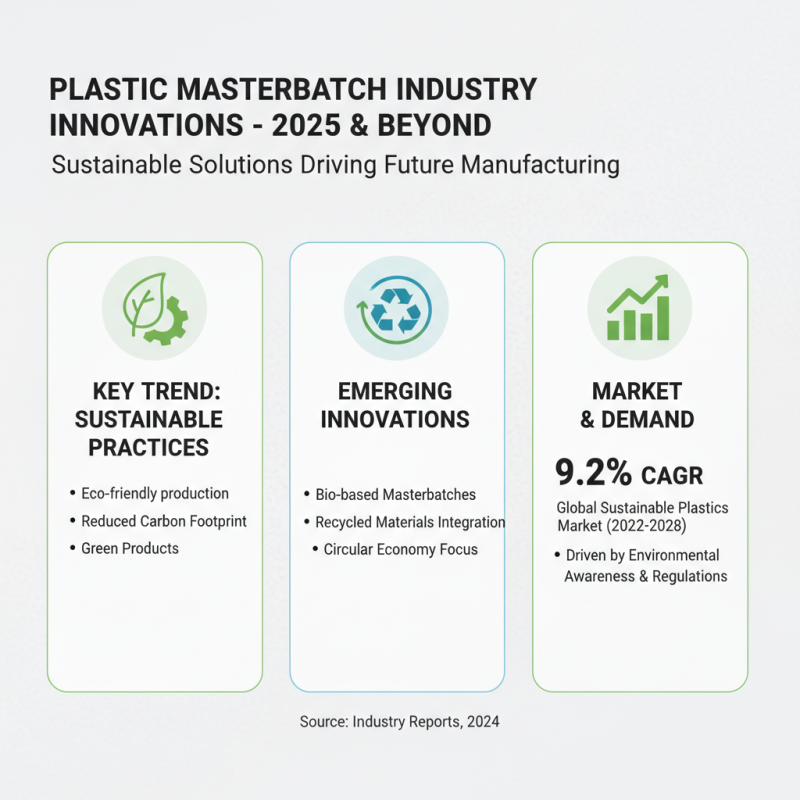

As we venture into 2025, the plastic masterbatch industry is poised for remarkable innovations that are set to revolutionize manufacturing processes and product offerings. A significant trend emerging is the integration of sustainable practices in masterbatch production. Industry reports suggest that the global demand for sustainable plastics is anticipated to grow at a CAGR of 9.2% from 2022 to 2028, driven by increasing environmental awareness and regulatory pressures. Innovations such as bio-based masterbatches and those incorporating recycled materials are becoming more prevalent, helping manufacturers reduce their carbon footprint while satisfying consumers' demands for green products.

Additionally, technological advancements in color masterbatch and additive masterbatch formulations are visibly evolving. A recent evaluation indicated that advancements in nanotechnology and polymer science are leading to the development of high-performance masterbatches that offer superior thermal stability, UV protection, and enhanced pigmentation at lower loadings. This not only optimizes production efficiency but also enhances the quality and longevity of plastic products.

Tip: Consider investing in R&D for sustainable masterbatch solutions; it's not just a trend but a critical pathway for future competitiveness in the industry. Furthermore, stay updated on regulatory changes concerning plastic usage to align your product offerings accordingly.

Projected Market Growth: Statistics on Plastic Masterbatch Demand

The demand for plastic masterbatch is projected to surge significantly in the coming years, driven by its crucial role in enhancing the properties of plastic. The global plastic masterbatch market is anticipated to reach unprecedented growth figures, with estimates indicating a compound annual growth rate (CAGR) that reflects an increasing reliance on this technology across various manufacturing sectors. The expanding applications in packaging, automotive, and consumer goods are expected to fuel this growth, highlighting the essential role that masterbatches play in improving color, additives, and functional performance of plastics.

Tip: When considering the use of plastic masterbatch in your operations, it's important to assess the specific requirements of your product line. Understanding the desired characteristics of the final product, such as color intensity, UV stability, or thermal resistance, can guide you in selecting the appropriate type of masterbatch, which ultimately affects product quality and performance.

Furthermore, sustainability trends are influencing market dynamics, with a growing emphasis on biodegradable and recycled materials. This shift not only responds to consumer demands for environmentally friendly options but also opens avenues for innovation in plastic masterbatch formulations. Adopting sustainable practices in production can enhance brand reputation and align with regulatory standards while contributing positively to the market growth of eco-conscious goods.

Tip: Engaging in research on sustainable masterbatch solutions can lead to competitive advantages. Collaborating with suppliers who prioritize environmental responsibility can provide both innovation and credibility in today’s eco-sensitive market landscape.

2025 Top Trends in Plastic Masterbatch and Its Impact on the Industry - Projected Market Growth

| Trend | Projected Growth Rate (%) | Key Applications | Region with Highest Demand | Market Size (Million USD) |

|---|---|---|---|---|

| Sustainable Masterbatch | 12% | Packaging, Consumer Goods | North America | 3200 |

| Color Concentrates | 8% | Automotive, Construction | Asia-Pacific | 2500 |

| Specialty Masterbatch | 10% | Medical Devices, Electronics | Europe | 1800 |

| Additive Masterbatch | 9% | Agriculture, Infrastructure | Latin America | 1500 |

| Recycled Masterbatch | 15% | Packaging, Textiles | Middle East & Africa | 1100 |

Sustainability Trends: Biodegradable Masterbatches and Industry Adaptation

The growing focus on sustainability within the plastic industry is influencing the development and adaptation of biodegradable masterbatches. As environmental concerns rise, manufacturers are increasingly turning to natural raw materials that break down more efficiently than traditional plastics. This shift not only meets consumer demand for eco-friendly products but also aligns with regulatory pressures aimed at reducing plastic waste. Biodegradable masterbatches represent a promising solution, allowing standard plastics to incorporate sustainable elements without significant changes to existing manufacturing processes.

Tips for businesses looking to transition to biodegradable masterbatches include:

- Conducting thorough research on various material options available.

- Engaging with suppliers who specialize in sustainable solutions can provide valuable insights into the latest advancements.

- Investing in employee training to understand the specific processing requirements and impact of these new materials on production lines.

Adapting to these sustainability trends also involves rethinking marketing strategies. Communicating the benefits of biodegradable products clearly to consumers can foster trust and brand loyalty. Educating the market about the lifecycle of these materials and their proper disposal will enhance consumer understanding and acceptance, ultimately driving the demand for greener products in the plastic industry.

Technological Advancements: Impact of AI and Automation on Production

The growing integration of artificial intelligence (AI) and automation in the production of plastic masterbatch is poised to transform the industry by enhancing efficiency and reducing costs. According to a recent report by Markets and Markets, the AI in the manufacturing market is expected to reach USD 16.7 billion by 2026, with a compound annual growth rate (CAGR) of 25.5%. This surge is indicative of the significant potential that AI holds for revolutionizing production processes, including precision mixing and real-time quality control in masterbatch production.

Automation also plays a critical role in optimizing production lines. With the adoption of advanced robotics and IoT-enabled machinery, manufacturers can achieve greater operational efficiency and minimize human errors. A study by Grand View Research reports that the global automation market in manufacturing is projected to grow to USD 200 billion by 2028. Implementing these technologies not only streamlines workflows but also provides valuable insights through data analytics, which can lead to improved product formulations and sustainability practices.

Tips: To stay ahead in this evolving landscape, companies should invest in upgrading their systems to incorporate AI and automation technologies. Additionally, continuous training for staff on these new tools can facilitate a smoother transition and increased productivity. Keeping abreast of industry trends and reports can also help in making informed decisions that align with the future direction of plastic masterbatch production.

2025 Top Trends in Plastic Masterbatch and Its Impact on the Industry

This bar chart illustrates the projected growth trends in various segments of plastic masterbatch production driven by technological advancements such as AI and automation. The data represents the percentage increase in production capacity over the years 2023 to 2025.

Regulatory Changes: How Policy Is Shaping Plastic Masterbatch Practices

The regulatory landscape surrounding plastic masterbatch is evolving rapidly, significantly influencing production practices and innovation within the industry. Governments worldwide are implementing stricter guidelines aimed at reducing environmental impacts, which directly affects how manufacturers formulate and utilize masterbatches. Policies focusing on sustainability are pushing companies to prioritize eco-friendly materials and production processes, leading to increased research and development of bio-based alternatives.

Moreover, compliance with regulations such as the EU's REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is becoming increasingly essential. These regulations not only demand transparency regarding chemical compositions but also necessitate companies to adopt safer and more sustainable practices throughout their supply chains.

As a result, manufacturers are pressured to innovate in their recycling processes and reduce the carbon footprint of their products, ultimately reshaping the entire industry towards more sustainable practices. The adaptation to these regulatory changes not only ensures compliance but also positions companies as leaders in a market that increasingly values environmental responsibility.

Related Posts

-

Why Plastic Additives Are Essential for Enhancing Material Performance

-

Exploring the Future of Sustainability with Bio Plastics and Their Impact on Our Environment

-

Unlocking the Power of Hips Compound: A Comprehensive Guide to Enhanced Performance and Health

-

The Science Behind Black Masterbatch: Revolutionizing Polymer Coloration Techniques

-

2025 Top Trends in Plastic Compound Innovations and Applications

-

2025 Guide: How to Choose the Right Plastic for Your Plastic Ka Plastic Needs