Blog

2026 Top Trends in Compound for Plastic Innovation and Application?

The future of "compound for plastic" is on the brink of innovation. As sustainability takes center stage, experts emphasize the need for advanced materials. Dr. Emily Chang, a noted researcher in this field, states, "Innovations in compound for plastic can redefine our environmental impact."

Various trends are emerging, focusing on biodegradable ingredients and improved recyclability. The demand for eco-friendly options is increasing. Companies face the challenge of balancing cost and functionality. New compounds must perform as well as traditional plastics while being kinder to the planet. Addressing this complex issue will require collaboration across industries.

Despite the exciting advancements, there are flaws in current methods. Many compounds still lack complete biodegradability. Some innovations may be costly to produce. The industry must reflect on these shortcomings. As 2026 approaches, the path for "compound for plastic" innovation remains both promising and precarious.

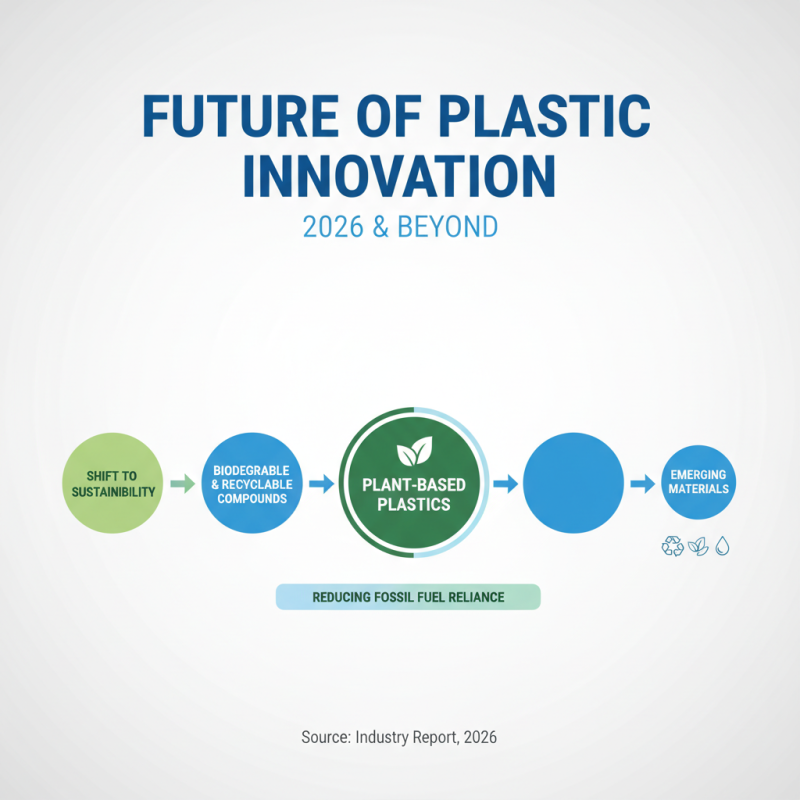

Emerging Materials and Technologies in Plastic Compounds for 2026

The landscape of plastic innovation is rapidly changing. In 2026, we can expect a surge in biodegradable and recyclable compounds. Emerging materials like plant-based plastics will take center stage. These innovations aim to reduce our reliance on fossil fuels.

Recycling technologies are advancing too. Innovations like chemical recycling can break down plastics into their core components. This method can enhance the circular economy. Yet, many challenges remain. Not all recycling processes are efficient or cost-effective. Industry must address these flaws to achieve real sustainability.

**Tip**: Always keep an eye on new startups in the material science sector. They often drive the most innovative solutions. Engaging with new technologies may offer surprising benefits.

Additionally, composites made from natural fibers are gaining traction. They provide strength and are lightweight, perfect for automotive and consumer goods. However, some may question their durability. Testing these materials is crucial. Are they as long-lasting as traditional options?

**Tip**: Conduct thorough evaluations before integrating new materials. Real-world performance can differ significantly from laboratory results. Be prepared for adjustments in your applications.

Sustainability Trends Driving Innovation in Plastic Applications

The drive for sustainability is reshaping the plastic industry. An increasing number of companies are turning to recycled materials and bio-based options. Reports show that by 2026, the global market for sustainable plastic applications is expected to exceed $500 billion. This shift is crucial for reducing plastic waste and carbon footprints.

Many organizations are exploring innovative methods to recycle plastics. Advanced recycling technologies now allow manufacturers to reclaim and reuse plastics more efficiently. For instance, mechanical recycling can recover about 70% of plastics in some systems. Yet, challenges remain. Not all plastics are easily recyclable, leading to a significant amount of material still ending up in landfills.

Tips: Consider the potential of biodegradable plastics. They can break down naturally, reducing environmental impact. Explore partnerships with firms focused on eco-friendly practices. Engage consumers in sustainability efforts for better impact. Encouraging more responsible behaviors is vital in fostering a culture of recycling.

The transition to sustainable plastic applications requires collaboration and innovation. Efforts must be made to educate both consumers and businesses. While progress is being made, a lot of work remains. Reflect on how these changes can create a more sustainable future for plastics. The market is evolving, but true transformation requires commitment from all stakeholders involved.

Advancements in Biodegradable and Bio-based Plastics

The fast evolution in biodegradable and bio-based plastics showcases a significant shift in material science. Reports highlight that the global market for biodegradable plastics is projected to reach $6.5 billion by 2027, growing at a CAGR of 10%. This rising interest isn't without challenges. Many bio-based plastics still face issues related to their performance compared to conventional plastics.

Research shows that compostable plastics can take longer to decompose than expected. In real-world conditions, specific biodegradation rates are often slower than those in laboratory settings. Furthermore, the reliance on agricultural resources raises concerns over food supply. In 2021, around 38% of bio-based plastics derived from corn were criticized for competing with food crops.

Innovations like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are promising, yet questions about scalability linger. Some industry experts point out that while production techniques are improving, the environmental impact of sourcing materials must be addressed. The balance between advancing technology and sustainable practices remains a critical challenge in this sector.

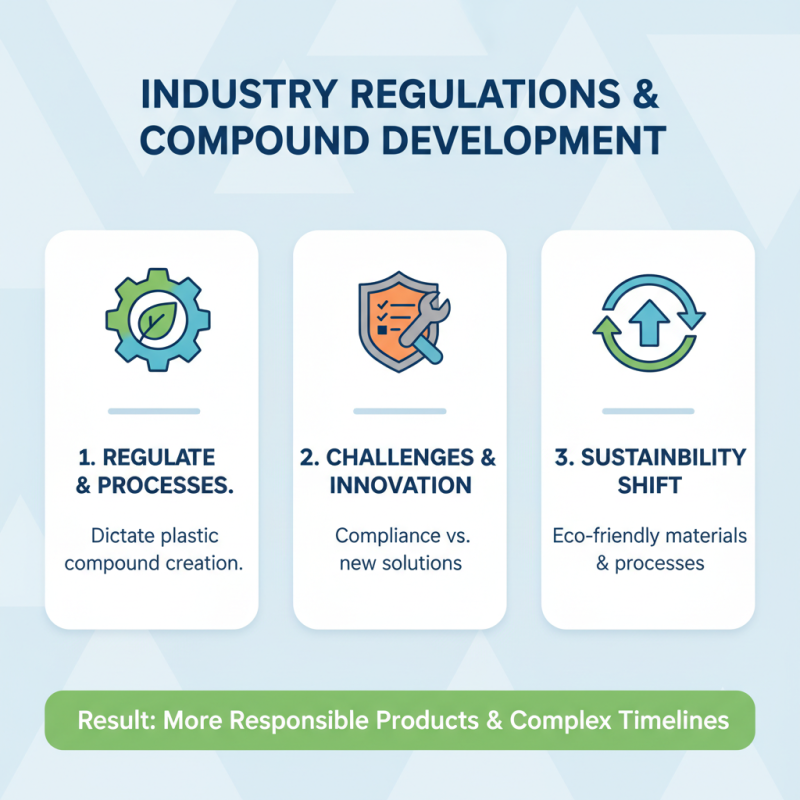

Impact of Industry Regulations on Compound Development

The impact of industry regulations on compound development is significant. These regulations dictate the materials and processes used in creating plastic compounds. Companies face challenges in complying with these standards while remaining innovative. Some regulations push for sustainable practices, requiring new materials or processes that reduce environmental impact. This shift can complicate development timelines but often leads to more responsible products.

Innovation in plastic compounds is also shaped by these regulations. As companies seek to meet compliance, they may experiment with novel formulations. Some approaches succeed, while others fall short of expectations. This trial-and-error process highlights the complexity of balancing creativity and compliance. The need for careful consideration increases, often resulting in setbacks.

Despite these hurdles, the industry is learning and evolving. Companies are adopting more transparent processes, sharing successes and failures. This openness fosters collaboration within the sector and promotes a culture of learning. As regulations continue to change, the focus will remain on developing compounds that meet both compliance and consumer demands.

Future Applications of Smart Plastics and Additive Technologies

The future of smart plastics and additive technologies looks promising. Recent reports suggest that the global smart plastics market will reach nearly $30 billion by 2026. This growth stems from their increasing applications in healthcare, automotive, and electronics. Smart plastics can adapt to environmental changes, providing unique functionalities. For example, thermochromic materials change color with temperature fluctuations. Such features offer exciting possibilities for interactive packaging and wearables.

Additive manufacturing, or 3D printing, is revolutionizing plastic applications. The industry is projected to grow significantly, fueled by the demand for customized products. In 2023, 3D printing accounted for approximately 5% of the global plastic market. However, challenges persist, such as material limitations and waste management. Many additive technologies struggle with producing high-quality finished products consistently. This inconsistency raises concerns about durability and performance.

The intersection of smart plastics and additive technologies presents many opportunities. Combining these innovations could lead to new materials that sense and respond to their environment. However, the industry must reflect on sustainability. Recycling and biodegradability are crucial for future developments. Stakeholders need to balance innovation and environmental responsibility in this evolving landscape.

2026 Top Trends in Compound for Plastic Innovation and Application

| Trend | Description | Application Areas | Impact on Sustainability |

|---|---|---|---|

| Smart Plastics | Plastics embedded with sensors for real-time data collection. | Healthcare, Packaging, Wearable Tech | Enhances recycling processes and materials tracking. |

| Biodegradable Compounds | Plastics designed to decompose naturally in the environment. | Agriculture, Consumer Goods, Food Packaging | Reduces landfill waste and pollution. |

| Recycled Plastic Innovations | Advanced methods for recycling plastics into high-quality materials. | Construction, Automotive, Consumer Products | Promotes a circular economy. |

| Additive Manufacturing | 3D printing technologies using advanced plastic composites. | Aerospace, Medical Devices, Prototyping | Supports custom solutions and reduces waste. |

| Self-healing Polymers | Materials that can repair themselves after damage. | Automotive, Electronics, Infrastructure | Increases longevity of products, reducing waste. |

Related Posts

-

Top Compounds for Plastic in 2025 What You Need to Know

-

Exploring the Future: Innovations in Plastic Compound Technology for Sustainable Manufacturing

-

2025 Top Trends in Plastic Compound Innovations and Applications

-

Top 10 Benefits of Using Plastic Compounds in Modern Manufacturing

-

How to Choose the Right Plastic Compound for Your Project?

-

How to Choose Bioplastic Packaging for Your Sustainable Business Needs?