Blog

What Are the Benefits of Using PP Plastic in Everyday Products?

PP plastic is widely used in our daily lives. Its benefits are numerous, making it a popular choice for manufacturers. This material is lightweight yet strong, offering durability for various applications. Many everyday products, from containers to automotive parts, utilize PP plastic for its resilience.

The versatility of PP plastic stands out. It can be molded into different shapes, supporting different designs. This adaptability is essential for packaging and consumer goods. However, the environmental impact of PP plastic raises concerns. While it serves many purposes, its disposal and recycling are challenging.

As we embrace PP plastic, we must consider these challenges. The convenience of using this material must be balanced with our responsibility to the environment. Reflecting on this can help us make better choices in our consumption.

Understanding Polypropylene (PP) Plastic and Its Properties

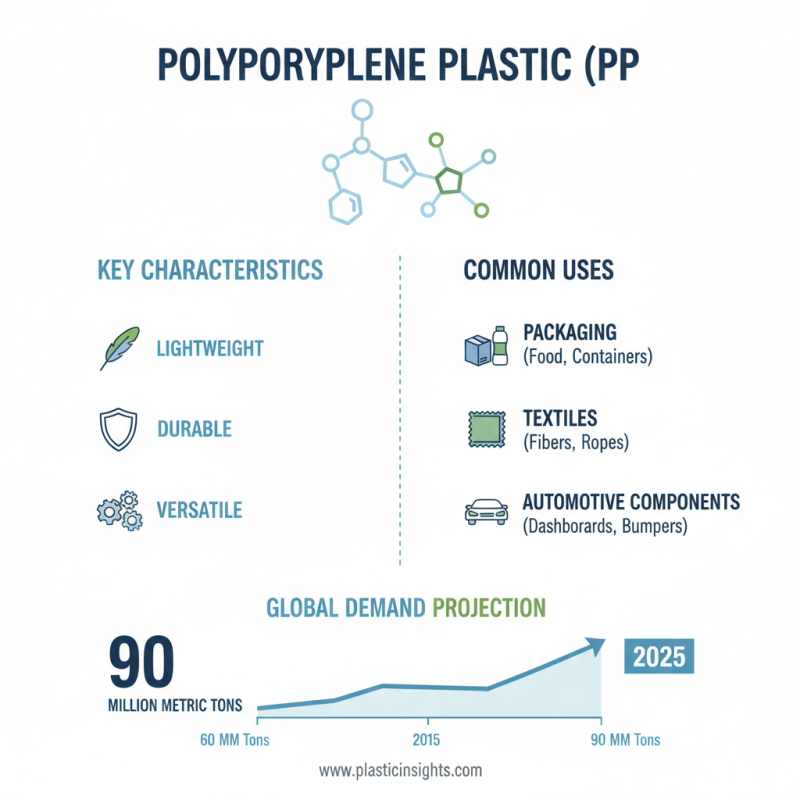

Polypropylene (PP) plastic is a versatile material used in many everyday products. It is lightweight and durable, which makes it ideal for packaging, textiles, and automotive components. According to industry reports, the global demand for PP plastic is projected to reach 90 million metric tons by 2025. This growth reflects its widespread use and effectiveness.

PP plastic boasts several key properties. It is resistant to chemicals, moisture, and heat. These characteristics provide an edge in various applications. For instance, PP is commonly used in food containers due to its low moisture absorption and excellent barrier properties. However, while PP is recyclable, the awareness and infrastructure for recycling it vary significantly across regions.

Furthermore, the production of PP emits greenhouse gases. In fact, studies show that the process can generate over 1.5 tons of carbon dioxide for every ton of PP produced. This raises questions about sustainability versus utility. As consumers, we must reflect on this balance. The benefits of PP need to be weighed against its environmental impact.

Common Applications of PP Plastic in Everyday Products

Polypropylene (PP) plastic is widely used in everyday products. Its versatility makes it a popular choice across various industries. You'll find PP plastic in containers, toys, and automotive parts. Its durability and resistance to chemicals are significant advantages. For instance, food containers often use PP because it can withstand heat and is microwave safe.

In the household, PP plastic is present in many forms. Think of your dishwasher-safe kitchenware or the caps on bottles. These applications highlight its practicality and user-friendliness. Additionally, PP is lightweight, making it easy to handle. Yet, the environmental impact of PP production raises concerns. Recycling options exist but are often underutilized.

The presence of PP plastic in our lives is undeniable. It contributes to convenience but also prompts reflection. Are we aware of how much we consume? As we use more disposable products, we should consider a more sustainable approach. Balancing convenience with environmental responsibility is crucial for future generations.

Benefits of Using PP Plastic in Everyday Products

The following chart illustrates the various benefits of using polypropylene (PP) plastic in everyday products, along with their respective usage percentages in common applications.

Environmental Advantages of Using PP Plastic

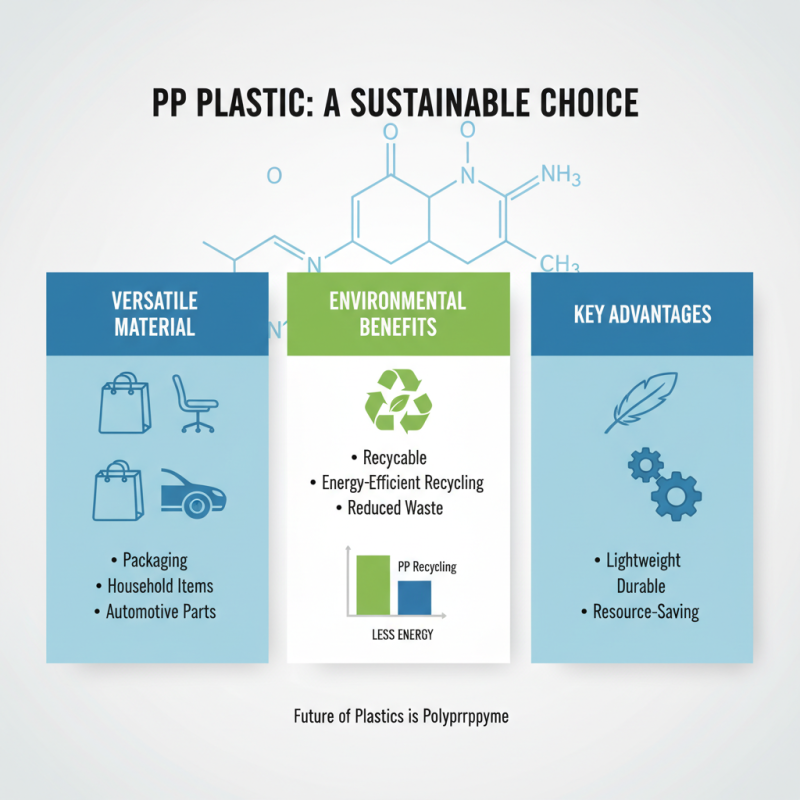

PP plastic, known as polypropylene, has gained attention for its environmental benefits. This lightweight material is highly versatile. It's used in packaging, household items, and even automotive parts. Unlike other plastics, PP is recyclable. Its recycling process is more efficient and consumes less energy.

One significant environmental advantage is its durability. PP plastic is resistant to many chemical solvents, bases, and acids. This property means products made from PP can last longer. However, this durability can also be a double-edged sword. When discarded improperly, it can persist in the environment for many years. This raises questions about recycling practices.

Additionally, PP plastic can help reduce waste. It is often used to create reusable containers and bags. These alternatives can replace single-use plastics in our daily lives. Using PP instead of other materials can result in less overall waste. Still, awareness around proper disposal remains crucial. Consumer education on recycling can further enhance the benefits of PP plastic.

Health and Safety Aspects of PP Plastic

Polypropylene (PP) plastic is widely used in many products, but health and safety aspects are crucial. PP plastic is often considered safer than other plastics. It has low toxicity levels and does not leach harmful chemicals in food storage. According to the American Chemistry Council, PP is approved for food contact applications by the FDA.

While PP is relatively safe, concerns still exist. Some reports suggest improper recycling can lead to contamination. The recycling process for PP is not always efficient. Not all PP items are recycled properly, and improper recycling can release microplastics into the environment. These microplastics may pose potential health risks.

Tip: Always check recycling guidelines before disposing of PP products.

PP is durable but not unbreakable. Continuous exposure to sunlight can degrade it over time. This degradation can produce harmful particles. It’s critical to use PP products within their lifespan to minimize risks.

Tip: Use PP items as directed and store them away from direct sunlight to extend their life.

Consumer awareness is key when using PP products. Understanding potential risks can help ensure safe usage. Research shows that responsible disposal can significantly mitigate environmental impact.

Cost-Effectiveness of PP Plastic in Manufacturing

Polypropylene (PP) plastic has become a game changer in manufacturing processes. Its cost-effectiveness is a significant factor. According to industry reports, PP can reduce production costs by up to 30%. This is a major advantage for manufacturers looking to optimize budgets. The material's lightweight nature also cuts down on transportation costs. Lightweight shipments mean less fuel usage and lower emissions.

Durability is another benefit worth noting. PP has a high resistance to chemicals and fatigue. This contributes to longer product life spans, ultimately saving replacement costs. A report by the Plastics Industry Association highlights that products made from PP can last 25% longer than those made from other materials. However, its recyclability can be an area for improvement. While many PP products are recyclable, collection systems vary widely. This inconsistency can lead to waste and missed opportunities for reuse.

Moreover, while PP's versatility is a strength, it sometimes creates challenges. This plastic can be molded into various forms, but not all applications maximize its potential. Some designs may ignore its properties, resulting in inefficiencies. Manufacturers must consider how to innovate and effectively utilize PP to fully embrace its cost benefits. This balancing act between cost and performance remains a crucial aspect of modern manufacturing practices.

Related Posts

-

2025 Top 10 Anti Retardant Products for Enhanced Safety and Performance

-

The Science Behind Black Masterbatch: Revolutionizing Polymer Coloration Techniques

-

How to Recycle Plastic Effectively: A Comprehensive Guide to Plastic Waste Management

-

2025 Top Color Masterbatch Trends Every Manufacturer Should Know

-

Top 5 Conductive Compounds for Enhanced Electrical Performance in 2023

-

Exploring the 2025 Top Types of Plastics in Our Ever-Changing Plastic World