Blog

Best Colored Plastics Guide for Your Projects and Crafts

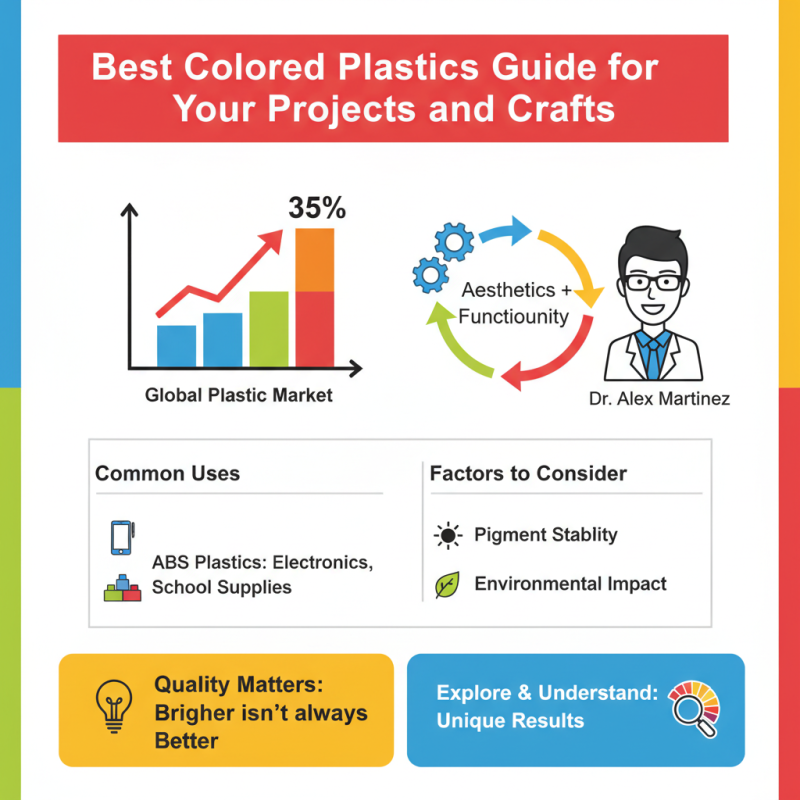

In the world of design and crafting, the significance of "plastic with color" cannot be overstated. Recent industry reports indicate that colored plastics account for approximately 35% of the global plastic market. This growing trend attracts artists and manufacturers alike. Experts emphasize the importance of choosing the right materials. Dr. Alex Martinez, a leading figure in materials science, stated, "The choice of color in plastic impacts not just aesthetics, but functionality too."

Crafts and projects often rely heavily on colored plastics for their vibrancy and versatility. For instance, colored ABS plastics are used in everything from consumer electronics to school supplies. The aesthetic appeal of these materials enhances many creative endeavors. Yet, not all colored plastics perform equally. Factors such as pigment stability and environmental impact must be considered carefully.

Sometimes, users may overlook the importance of quality. A brighter color may not always mean better performance. Inconsistent quality can lead to frustrating experiences in projects. Exploring the full universe of colored plastics can be daunting but rewarding. Each choice leads to unique results. Understanding the characteristics of these materials is essential for success.

Best Colored Plastics: Understanding Types and Their Properties

When selecting colored plastics for crafts, it's crucial to understand their types and properties. Different plastics serve varied purposes. For example, acrylic is known for its clarity and glossy finish. It's lightweight yet durable. Polypropylene is another option. It offers a good balance of flexibility and strength, making it ideal for many projects.

According to a recent industry report, the market for colored plastics is expected to grow by 5% annually. This suggests increasing demand for vibrant hues in consumer products. However, not all colored plastics are created equal. Some may fade over time or become brittle under UV exposure. It's important to match the material with the intended use.

Remember, aesthetic appeal is just one aspect. Properties like melting point and impact resistance matter too. For instance, PVC is often used for outdoor projects due to its resistance to weather and chemicals. Yet, it may not be ideal for environments with extreme temperatures. Often, the choice of plastic requires careful consideration of both form and function. A balance is needed to achieve the desired outcome.

Key Considerations for Choosing the Right Colored Plastic for Crafts

When choosing colored plastic for your crafts, several key considerations come into play. First, think about the project’s purpose. Will the plastic be used indoors or outdoors? Outdoor projects need UV-resistant materials to withstand sunlight. Indoor crafts can afford more flexibility in color and finish.

Tip: Always test the plastic in a small area first. Different plastics behave differently under paint or adhesives. Not all colors adhere well to every material. Consider how the plastic will be cut and shaped. Thinner plastic might be more flexible but can warp easily when heated.

Color selection is vital too. Bright colors can enhance a project’s appeal. Pastel shades might create a softer look. Don’t shy away from mixing colors, but be aware of how they work together. Unexpected pairings can yield fantastic outcomes, yet they may also fall flat.

Tip: Keep a color wheel handy. It helps in visualizing combinations. Sometimes, what looks good in theory doesn’t work in practice. Reflect on your choices as you work. Adjusting color schemes mid-project can lead to delightful surprises.

Industry Standards for Color Consistency in Plastic Manufacturing

Color consistency is vital in plastic manufacturing. According to the "Plastic Color Matching Study" by the Plastics Industry Association, color variations can lead to significant production inefficiencies. These discrepancies may affect product quality and customer satisfaction. Consistency is key. Deviations can result in rework, wasted materials, and increased costs.

The American Society for Testing and Materials (ASTM) outlines standards for color measurement. The use of color matching systems is essential for achieving consistency. Reports indicate that over 30% of manufacturers struggle with color matching. This issue can compromise brand identity and consumer trust. Proper training and equipment can mitigate these challenges.

Additionally, environmental factors play a role in color stability. Temperature and humidity can alter the final appearance of plastic products. It's crucial for manufacturers to monitor these elements closely. Regular audits can be beneficial, but they are often overlooked. Investing time in understanding color consistency can yield long-term benefits.

Best Colored Plastics Guide for Your Projects and Crafts - Industry Standards for Color Consistency in Plastic Manufacturing

| Color | Material Type | Common Uses | Color Consistency Rating |

|---|---|---|---|

| Red | Acrylic | Display signs, decorative items | High |

| Blue | Polycarbonate | Safety shields, eyewear | Moderate |

| Green | PVC | Outdoor furniture, landscaping | High |

| Yellow | Polypropylene | Containers, toys | Moderate |

| Black | HIPS | Casings, decorative elements | High |

| White | ABS | Household items, models | Very High |

Processing Techniques for Colored Plastics: An Overview

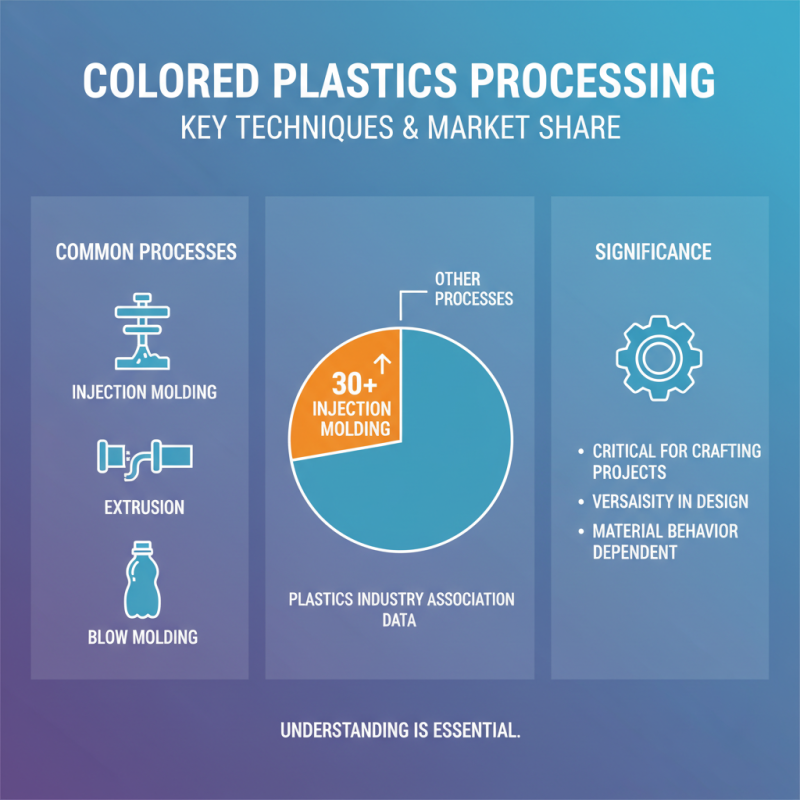

When working with colored plastics, understanding processing techniques is essential. Various methods contribute to how colored plastics behave. Common processes include injection molding, extrusion, and blow molding. Data from the Plastics Industry Association shows that injection molding accounts for over 30% of the plastic processing market. This highlights its significance for crafting projects.

Injection molding allows for intricate designs. It is effective for high-volume production. However, precision is crucial. Any miscalculations can lead to wasted materials. Extrusion can create long shapes, like tubing. This process is versatile but can result in uneven coloration if not monitored closely. Blow molding is popular for creating hollow shapes. Each method offers unique possibilities while presenting challenges.

Tips: Always test small batches before full-scale production. Monitor temperatures and speeds closely to avoid defects. Remember, color consistency is key for aesthetics. Each technique requires learning curves, and mistakes happen. Reflecting on these can improve your results. Embrace imperfections as learning opportunities.

Applications of Colored Plastics in Arts and Design: Trends and Data

Colored plastics are becoming increasingly relevant in arts and design. According to a recent industry report, the market for colored plastics is expected to grow by 5% annually over the next five years. This trend reflects a growing demand from designers looking for vibrant, durable materials to bring their concepts to life. Custom colors contribute significantly to this sector, allowing artists to express their creativity freely.

However, not all applications are without challenges. Some colored plastics can fade when exposed to sunlight. Maintaining color integrity becomes crucial for outdoor projects. Data indicates that roughly 30% of designers switch materials mid-project due to color fading concerns. Additionally, a lack of standardization in color matching presents hurdles. Artists often find themselves frustrated when trying to replicate specific shades across different batches.

Despite these issues, the versatility of colored plastics remains a strong point. They offer a range of textures and finishes. This variety can elevate a project, driving innovative design solutions. Designers are increasingly exploring techniques like layering, which allow for unique visual effects. Continued experimentation helps push boundaries, turning potential setbacks into opportunities for learning and growth.

Applications of Colored Plastics in Arts and Design

Related Posts

-

2025 Top Trends in Plastic Compound Innovations and Applications

-

Unlocking the Power of Hips Compound: A Comprehensive Guide to Enhanced Performance and Health

-

Understanding the Benefits of Compound Packaging for Sustainable Product Solutions

-

Exploring the Masterbatch Market: Trends, Innovations, and Future Growth Projections

-

2025 Guide: How to Choose the Right Plastic for Your Plastic Ka Plastic Needs

-

Top 10 Benefits of Using Plastic Compounds in Modern Manufacturing