Blog

2026 Best Conductive Compound Options for Your Projects?

In the evolving landscape of electronic engineering, the choice of a conductive compound can make or break a project. Experts like Dr. Emily Harper, a renowned materials scientist, emphasize this point: "Selecting the right conductive compound is crucial for optimal performance and longevity." With numerous options available, it’s essential to understand the unique properties of each compound.

Conductive compounds serve various applications, from circuit boards to sensors. These materials can enhance electrical conductivity, thermal stability, and chemical resistance. However, selecting the ideal compound often feels overwhelming. Some options excel in flexibility but lack high conductivity, making them unsuitable for certain projects. Others might be too rigid, restricting design possibilities.

As the industry grows, so do the challenges. Designers need to balance cost-effectiveness with performance. Reflecting on past projects, it's clear that even minor miscalculations in compound selection can lead to significant setbacks. Prioritizing material integrity and compatibility with project requirements remains vital. The journey to find the best conductive compound is not just a task, but a continuous learning process.

Overview of Conductive Compounds: Definition and Applications

Conductive compounds play a crucial role in many industries. They are materials that can conduct electricity or heat. These compounds include metals, polymers, and composites. Conductive compounds are widely used in electronics, automotive, and medical devices. According to a recent industry report, the global conductive polymer market is expected to reach $6 billion by 2025. This shows the growing demand for these materials.

In electronics, conductive compounds enable better performance and efficiency. They are used in sensors, circuits, and batteries. Their properties can influence the reliability of devices. Selecting the right compound is essential. Some compounds may not withstand high temperatures or mechanical stress. This can lead to failures in applications.

Tips: Always test your compound choice in real-world conditions. Assess the mechanical properties and thermal stability before finalizing your material. Don’t overlook the importance of compatibility with other materials in your design.

Conductive compounds are not without challenges. Some may have limited availability or can be expensive. Other issues include varying performance across different suppliers. Understanding these nuances is vital for any project. A well-researched selection can save time and resources.

Key Characteristics to Look for in Conductive Compounds

When selecting conductive compounds for your projects, key characteristics are essential. One vital aspect is electrical conductivity. The compound should effectively transfer current. Look for materials with low resistivity, which can enhance performance in electronic applications. Testing different compositions helps identify the best fit for specific needs.

Another critical factor is thermal stability. The compound should withstand high temperatures without degrading. This is especially important in applications with heat-generating components. A material that loses its properties under heat is not ideal. Additionally, consider adhesion properties. A compound that bonds well to substrates ensures durability and reliability in use.

Finally, processing characteristics deserve attention. Some compounds are easier to handle than others. They should be easy to mix and apply. Reflect on how the application methods might impact the final product. Trying different formulations can lead to unexpected insights. The right conductive compound may require some trial and error. Embrace the challenges as learning opportunities.

2026 Best Conductive Compound Options for Your Projects? - Key Characteristics to Look for in Conductive Compounds

| Compound Type | Conductivity (S/m) | Temperature Range (°C) | Viscosity (Pa·s) | Application |

|---|---|---|---|---|

| Silver Conductive Ink | 10^6 | -40 to 150 | 0.1 | Printed Electronics |

| Graphene Composite | 10^4 | -20 to 300 | 1.0 | Thermal Management |

| Carbon Black Filled Polymer | 10^2 | -40 to 120 | 0.5 | EMI Shielding |

| Copper Paste | 10^5 | -30 to 200 | 0.2 | Circuit Connections |

| Metallic Nanoparticles | 10^3 | -50 to 180 | 0.05 | Sensors |

Top 2026 Conductive Compound Options for Electronic Projects

When working on electronic projects, choosing the right conductive compound is crucial. These materials facilitate electrical connections, ensuring efficient performance. In 2026, various options stand out in this field, and each has unique properties that may suit different needs.

Silver-particle filled compounds offer excellent conductivity. They are often used in applications where high performance is non-negotiable. However, they can be costly and may require careful handling. Alternatively, carbon-based compounds provide a more affordable option. While they might not match silver's conductivity, they deliver adequate performance in many situations. Projects that demand flexibility can benefit from these materials, though their consistency can sometimes be a concern.

Metallic powders blended with polymers create another viable choice. They can enhance conductivity while maintaining a user-friendly application. Yet, achieving the right mix can be tricky. The balance between conductivity and workability needs careful consideration. No single compound is perfect for every project, and evaluating each option's pros and cons is essential for success. Making the right choice may involve trial and error, prompting ongoing reflection on performance.

Comparative Analysis of Conductive Compounds: Pros and Cons

Conductive compounds play a crucial role in various projects, especially in electronics and materials science. A comparative analysis reveals significant pros and cons associated with common conductive materials such as silver, copper, and carbon-based compounds.

Silver offers excellent conductivity, with a conductivity rating of about 63 x 10^6 S/m. However, its high cost can limit its practicality. In contrast, copper is more affordable and still provides commendable conductivity at approximately 58 x 10^6 S/m. But, copper can tarnish over time, diminishing its performance. Carbon-based compounds, while generally more economical, exhibit variable conductivity. Their performance greatly depends on their composition and structure.

Tips: When choosing a conductive compound, consider both short-term costs and long-term performance. Sometimes, the cheapest option isn't the best. Evaluate your project's specific needs carefully. Also, remember that production methods affect the final product's effectiveness. Prioritize research to understand how different compounds behave under various conditions.

Understanding the nuances of these materials can be challenging. Developers must remain cautious of trade-offs. New materials emerge frequently, and they may offer unforeseen advantages. Conduct thorough testing to avoid overlooking potential issues.

2026 Best Conductive Compound Options for Your Projects

This chart displays the electrical conductivity values of various conductive compounds suitable for projects in 2026. Each compound has its own advantages and disadvantages, making it crucial to select the right one based on project requirements.

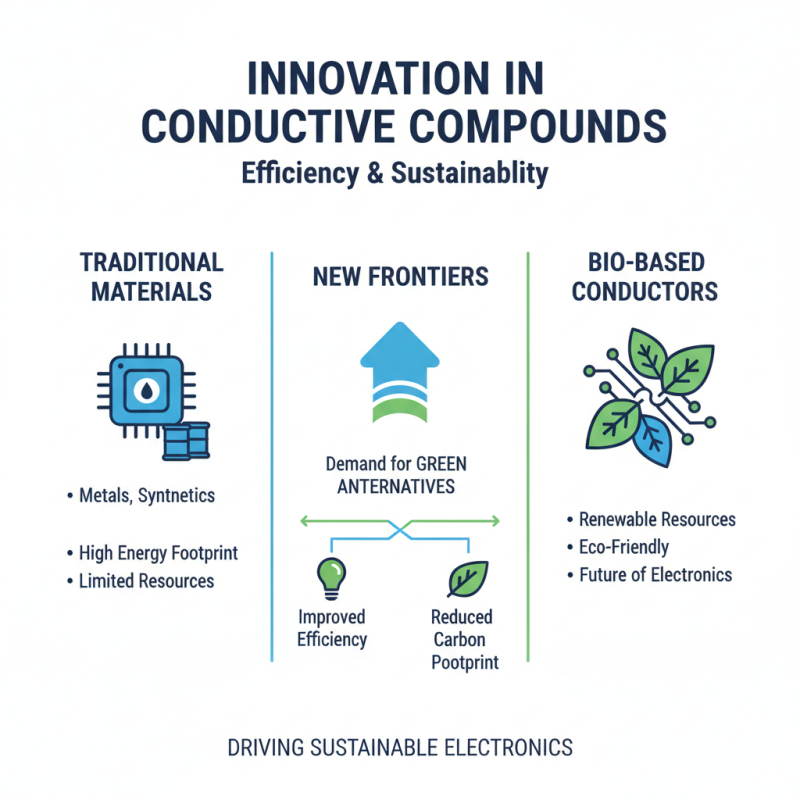

Future Trends in Conductive Compound Technology and Innovations

The landscape of conductive compounds is rapidly evolving. Innovations are driven by the demand for better efficiency and sustainability in electronics. One notable trend is the rise of bio-based conductive materials. These materials often come from renewable resources, which reduces environmental impact. As industries look to minimize their carbon footprint, this shift toward green alternatives is becoming critical.

New technologies are also changing how we use conductive compounds. Conductive inks, for instance, have expanded applications, from printed circuits to touch screens. Microstructuring techniques improve material performance, leading to increased functionality and reduced costs. However, challenges remain in scalability and consistency of these innovations. Finding the right balance between performance and environmental responsibility is essential.

As we look ahead to 2026, the focus will be on integrating advanced compounds in everyday applications. Smart textiles and flexible electronics may become standard. Staying aware of these advancements is necessary for project development. The future appears promising, yet uncertainties linger. Awareness and adaptability will define success in this evolving field.

Related Posts

-

Top 5 Conductive Compounds for Enhanced Electrical Performance in 2023

-

2025 Top 10 Anti Retardant Products for Enhanced Safety and Performance

-

Top Trends Driving Growth in the Masterbatch Market in 2023

-

How to Choose the Best Compound Packaging for Your Products

-

Understanding the Benefits of Compound Packaging for Sustainable Product Solutions

-

Tips to Reduce Plastic in Plastic Waste and Its Environmental Impact