Blog

Why Choose Filler Masterbatch for Your Plastic Manufacturing Needs?

In the rapidly evolving world of plastic manufacturing, the choice of materials can significantly impact both product quality and operational efficiency. One of the most effective solutions gaining traction among manufacturers is the use of filler masterbatch. According to a recent report by Industry Research, the global filler masterbatch market is projected to reach USD 3.5 billion by 2025, driven by an increasing demand for lightweight and cost-effective materials in various applications, from automotive components to consumer goods.

Industry experts advocate for the adoption of filler masterbatch due to its numerous advantages, such as improved mechanical properties and reduced production costs. Dr. Jane Smith, a renowned expert in polymer technology, emphasizes the importance of this material, stating, "Filler masterbatch not only enhances the physical properties of plastics but also significantly contributes to sustainability goals by reducing plastic consumption." Her insights highlight the dual benefits of using filler masterbatch: optimizing material usage and supporting environmental initiatives.

As manufacturers strive to innovate and meet market demands, the integration of filler masterbatch into their production processes can lead to enhanced performance and increased competitiveness. This introduction of filler masterbatch is not merely a trend; it represents a strategic shift towards more efficient and sustainable manufacturing practices, making it a pivotal choice for stakeholders in the plastic industry.

Understanding Filler Masterbatch and Its Composition

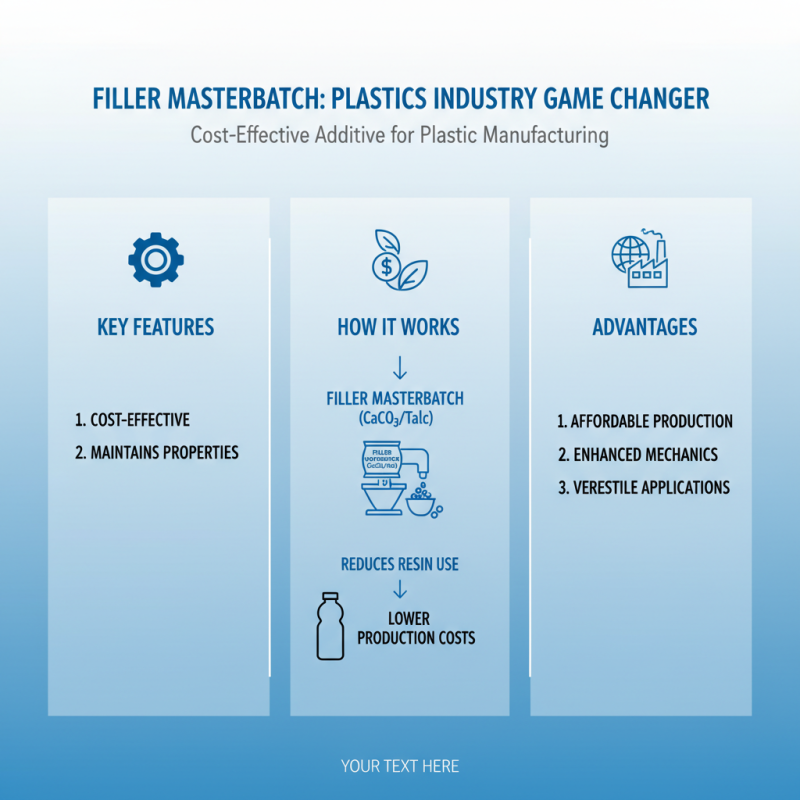

Filler masterbatch is an essential component in the plastic manufacturing process, primarily designed to enhance the properties of plastic products while reducing overall production costs. This concentrated mixture consists of fillers, such as calcium carbonate or talc, combined with a polymer carrier. The primary purpose of filler masterbatch is to modify the physical characteristics of plastics, improving tensile strength, rigidity, and heat resistance. By incorporating fillers, manufacturers can achieve desired material properties while optimizing material usage.

The composition of filler masterbatch plays a crucial role in its effectiveness. Fillers provide bulk and influence the plastic's density, while the carrier resin ensures compatibility within the final plastic product. The ratio of filler to carrier should be carefully calculated, as it directly affects the processing and performance of the final material. Additionally, fillers can be tailored to enhance specific qualities such as opacity, color, and surface finish, making filler masterbatch versatile for various applications. Understanding this composition allows manufacturers to select the appropriate type for their specific plastic manufacturing needs, ensuring that the final products meet industry standards and customer expectations.

Benefits of Using Filler Masterbatch in Plastic Manufacturing

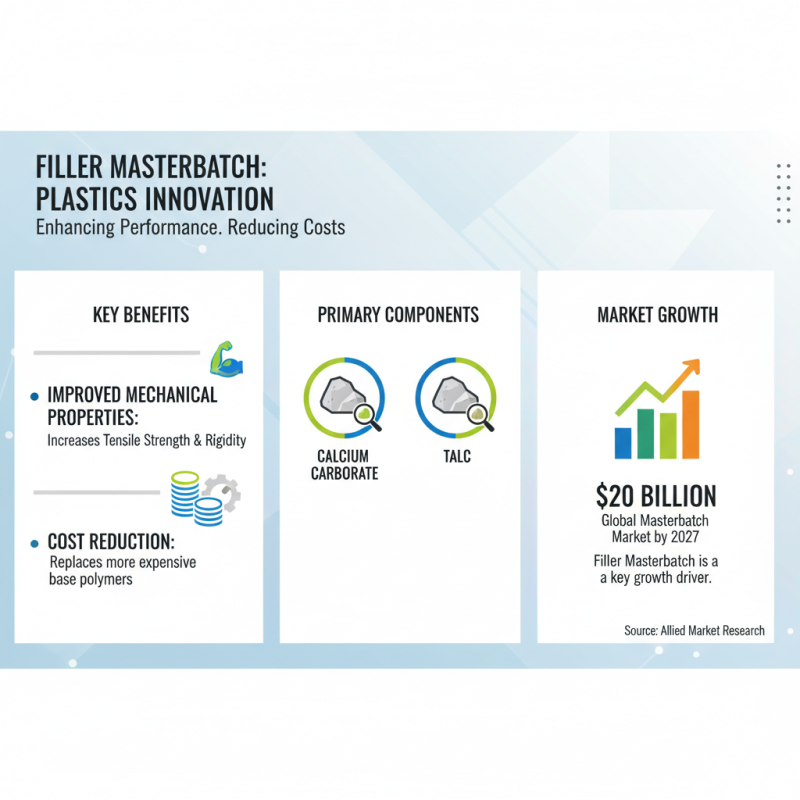

Filler masterbatch has gained considerable traction in the plastic manufacturing industry due to its ability to enhance product performance while reducing costs. One of the primary benefits of using filler masterbatch is its role in improving the mechanical properties of plastic products. According to a report by Allied Market Research, the global masterbatch market is projected to reach $20 billion by 2027, with filler masterbatch contributing significantly to this growth. By incorporating minerals such as calcium carbonate or talc, manufacturers can increase the tensile strength and rigidity of their plastics, resulting in products that withstand greater stress and strain.

Another key advantage of filler masterbatch is its cost-effectiveness. Utilizing filler materials can significantly reduce the overall material costs in production without compromising the quality of the final product. A study by Technavio estimates that integrating fillers can reduce raw material expenses by up to 30%, allowing manufacturers to offer competitive pricing in the market. Additionally, filler masterbatch can improve the processing characteristics of plastics, enhancing the flow during manufacturing and reducing cycle times. This efficiency translates to lower energy consumption and faster turnaround times, which are critical factors in today's fast-paced manufacturing environment.

Applications and Industries Utilizing Filler Masterbatch

Filler masterbatch has become an integral component in various industries due to its cost-effectiveness and versatility. It is widely utilized in the plastics sector, specifically in applications such as packaging, automotive parts, and consumer goods. According to a report by Market Research Future, the global filler masterbatch market is expected to reach a valuation of approximately USD 4.2 billion by 2025, growing at a CAGR of 6.2%. This growth is heavily driven by the increasing demand from the packaging industry, which employs filler masterbatch to enhance the mechanical properties and reduce the weight of plastic products without compromising quality.

The automotive industry is another significant sector where filler masterbatch is extensively used. By incorporating filler materials, manufacturers can produce lightweight components that help improve fuel efficiency and reduce emissions. The International Energy Agency estimates that reducing weight by just 10% in vehicles can improve fuel efficiency by 6-8%. Additionally, the construction industry has also recognized the benefits of filler masterbatch, utilizing it in composite materials for enhanced durability and performance. These applications highlight how filler masterbatch not only contributes to cost savings but also aligns with sustainability goals across various industries.

Filler Masterbatch Applications in Various Industries

Filler masterbatch is increasingly being utilized across various industries due to its cost-effectiveness and ability to enhance the properties of plastic products. The chart above illustrates the percentage of filler masterbatch usage in different sectors, highlighting its significance in packaging, consumer goods, construction, and automotive applications.

Comparison of Filler Masterbatch with Other Additives

Filler masterbatch has gained significant attention in the plastic manufacturing industry due to its unique advantages compared to other additives. One of the primary features of filler masterbatch is its cost-effectiveness. By incorporating fillers such as calcium carbonate or talc, manufacturers can reduce the reliance on more expensive resins. This not only lowers the overall cost of production but also maintains the required mechanical properties of the final product, making filler masterbatch an attractive option for various applications.

In contrast to color masterbatches or specialty additives, filler masterbatch offers enhanced processing efficiency without compromising quality. While color masterbatches are tailored for pigmentation, they often increase material costs and may require additional adjustments in the production process. Filler masterbatch, on the other hand, can seamlessly blend with polymers, improving flowability and reducing energy consumption during processing. Additionally, unlike some specialty additives that can lead to unexpected reactions or complications in formulation, filler masterbatch is typically more stable and easier to handle, proving to be a reliable choice for manufacturers seeking both performance and simplicity in their formulations.

Sustainability and Environmental Impact of Filler Masterbatch Usage

Filler masterbatch has emerged as a pioneering solution in the plastic manufacturing industry, particularly concerning sustainability and environmental impact. The incorporation of fillers such as calcium carbonate and talc not only reduces the volume of polymer used but also enhances the physical properties of the final products. According to a report by MarketsandMarkets, the global filler masterbatch market is expected to grow from USD 3.3 billion in 2021 to USD 4.9 billion by 2026, driven partly by the increasing demand for environmentally friendly alternatives in manufacturing processes.

The environmental benefits of using filler masterbatch are significant. By reducing the amount of virgin polymer required in production, manufacturers can significantly lower their carbon footprint. A study by the Plastics Industry Association indicates that incorporating fillers can reduce plastic consumption by up to 30%. Additionally, as recycling rates improve, the use of filler masterbatch helps create a more circular economy by making it easier to recycle plastics without compromising their quality. This contributes to waste reduction, aligning with global sustainability goals and showing a marked decrease in the overall environmental impact of plastic production and disposal.

Related Posts

-

The Hidden Role of Plastic Additives in Sustainable Material Innovation

-

How to Choose the Best Compound Packaging for Your Products

-

Exploring the Masterbatch Market: Trends, Innovations, and Future Growth Projections

-

Top 10 Benefits of Using Plastic Compounds in Modern Manufacturing

-

Exploring the Science Behind Color on Plastic: How Pigments Transform Materials

-

Unlocking the Power of Hips Compound: A Comprehensive Guide to Enhanced Performance and Health