Blog

How to Choose the Right Plastic Compound for Your Project?

Choosing the right plastic compound can seem daunting. According to Dr. Emily Chen, a leading expert in polymer science, “Selecting a plastic compound is critical to project success.” Her insights underline the importance of making informed decisions.

Plastic compounds vary widely. Different projects demand different properties, like strength, flexibility, or temperature resistance. For example, a project requiring high durability may lean towards reinforced materials. In contrast, projects emphasizing aesthetics might prioritize colors and textures.

However, the selection process is often complex. Many factors should be considered, such as environmental impact and cost efficiency. It’s easy to overlook small details. A simple oversight can lead to project delays or failures. Reflecting on these challenges can guide better decisions.

Understanding the Types of Plastic Compounds and Their Properties

Choosing the right plastic compound is crucial for any project's success. There are several types of plastic compounds, each with unique properties. For instance, polyethylene is lightweight and flexible. It is widely used for packaging. In contrast, polycarbonate is strong and impact-resistant, making it suitable for safety glasses. Understanding these differences helps inform your selection process.

Another essential type is polypropylene, known for its chemical resistance and durability. It is often used in automotive parts. On the other hand, PVC is versatile and can be rigid or flexible, depending on its formulation. However, not all applications are perfect matches. Sometimes, you might find that a material doesn’t meet all your expectations. You may need to experiment or reconsider your options.

While choosing, it’s also wise to reflect on the environment. Some plastics are recyclable, while others are not. Failure to consider this can lead to waste and environmental harm. Be open to feedback and adjust your material choices as needed. The world of plastics is broad and complex, and each decision can impact your project significantly. Always be ready to learn from your choices.

Material Properties Comparison of Common Plastic Compounds

This bar chart compares the tensile strength of common plastic compounds, which is a critical property to consider when selecting materials for various projects. ABS shows moderate strength, while Nylon has the highest tensile strength, making it suitable for more demanding applications.

Evaluating the Mechanical Strength and Durability Requirements

When selecting a plastic compound, mechanical strength and durability are crucial. Not every project demands the same level of toughness. For instance, components exposed to high stress need materials that can withstand heavy loads without deforming. Analyzing the specific requirements beforehand can save time and resources.

Consider how the plastic will be used. Will it face UV rays, chemicals, or extreme temperatures? Each factor can impact performance. Strength may matter, but so does resistance to wear and tear. Testing samples might reveal weaknesses that theoretical calculations miss.

Sometimes, compromises are necessary. A compound that is strong might lack flexibility, affecting its application. Adjusting your expectations and understanding the limitations is part of the process. Regular reassessment can lead to better choices in material selection.

Assessing Thermal and Chemical Resistance Factors in Plastics

When selecting a plastic compound for your project, thermal and chemical resistance play crucial roles. Different applications expose materials to varying temperatures and chemicals. You need to consider how plastics react under specific conditions. Some plastics can handle heat, while others may warp or melt. It’s essential to match the compound to your project's environment.

Think about the chemical exposure as well. Certain plastics resist solvents, acids, and bases better than others. For example, polypropylene has good resistance to many chemicals but may not fare well with strong oxidizers. Testing can reveal unexpected weaknesses. If a plastic is not up to par, it can lead to failure in critical structures.

Mistakes can happen during the selection process. Sometimes, assumptions are made without thorough testing. A brief review of properties may mislead you. Reflecting on the materials chosen can reveal alternative options that offer better resistance. Strive to gather as much data as possible. Remember, the right choice could mean the difference between success and failure in your project.

Considering Cost-Effectiveness and Availability in Material Selection

When selecting a plastic compound for any project, cost-effectiveness and availability are crucial factors. The price of materials can significantly affect your overall budget. Finding the right balance between quality and affordability can be challenging. Consider the different types of plastics available in the market. Some may seem cheaper upfront but can lead to higher costs in maintenance and replacements over time.

Availability is another essential aspect. Sourcing a specific plastic may not always be straightforward. Sometimes, what appears to be a cost-effective choice may be hard to find. You might face delays or inconsistencies in supply, which can derail your project timeline. It’s important to have alternative options ready. Local suppliers might offer faster access to materials than those requiring long shipping times.

Reflecting on past experiences can reveal valuable lessons. Perhaps you prioritized cost and faced issues with quality later. Maybe you overlooked the supply chain reliability of your chosen material. Each decision provides an opportunity to learn and improve your future selections. Balancing cost, quality, and availability requires continuous reevaluation and adaptation.

How to Choose the Right Plastic Compound for Your Project?

| Plastic Type | Common Applications | Cost per kg ($) | Availability | Strength (MPa) |

|---|---|---|---|---|

| Polypropylene (PP) | Packaging, automotive parts | 1.50 | Widely available | 30-50 |

| Polyethylene (PE) | Bags, containers | 1.00 | Overwhelmingly available | 20-30 |

| Polystyrene (PS) | Disposables, insulation | 1.20 | Readily available | 30-50 |

| Polyvinyl Chloride (PVC) | Pipes, medical equipment | 1.80 | Commonly available | 40-60 |

| Acrylonitrile Butadiene Styrene (ABS) | Toys, automotive parts | 2.00 | Easily accessible | 40-50 |

Analyzing Environmental Impact and Sustainability of Plastic Compounds

When selecting a plastic compound, the environmental impact cannot be overlooked. Many materials contribute to pollution and waste. In fact, a report by the World Economic Forum indicates that about 8 million tons of plastic end up in oceans each year. This is a stark reminder that our choices matter.

Biodegradable plastics have gained attention. They can decompose more quickly than conventional plastics. According to a study from the Ellen MacArthur Foundation, switching to biodegradable options could reduce plastic waste by 30% by 2030. However, the infrastructure for composting is still lacking in many areas, leading to challenges in their effective use.

Recycled plastics offer another avenue for sustainability. Using recycled materials cuts down on new plastic production. The Global Recycling Foundation reports that about 9% of plastic waste is currently recycled. This number needs to grow. Consumers often lack awareness about the recycling process, raising important questions about responsibility and education. Addressing these factors can lead to a better future for our environment.

Related Posts

-

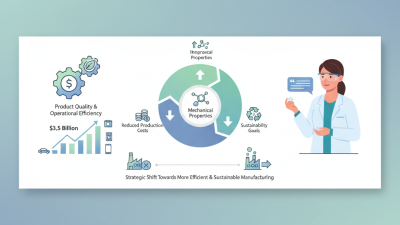

Why the Demand for Plastic Compounds is Surging in the Manufacturing Industry

-

Exploring the Future: Innovations in Plastic Compound Technology for Sustainable Manufacturing

-

2025 Top Trends in Plastic Compound Innovations and Applications

-

Top 10 Benefits of Using Plastic Compounds in Modern Manufacturing

-

Why Plastic Additives Are Essential for Enhancing Material Performance

-

Why Choose Filler Masterbatch for Your Plastic Manufacturing Needs?