Blog

How to Choose the Right Plastic Additives for Your Manufacturing Needs

In the ever-evolving landscape of manufacturing, the selection of appropriate plastic additives is crucial for enhancing the performance, durability, and aesthetic appeal of plastic products. According to a report by Smithers, the global market for plastic additives is projected to reach $50 billion by 2025, driven by the increasing demand for high-performance materials across various industries such as automotive, construction, and consumer goods. Plastic additives can significantly influence the processing and end-use properties of polymers, including flexibility, UV resistance, flame retardancy, and color stability.

As manufacturers strive to meet stringent regulatory standards and rising consumer expectations, understanding the diverse range of plastic additives available becomes paramount. Recent studies highlight that the correct formulation of plastic additives can improve the sustainability of plastic products by extending their lifecycle and enabling recyclability. Moreover, with innovations in nanotechnology and bioplastics emerging, the landscape of plastic additives is becoming increasingly complex, necessitating a strategic approach to selection. With this guide, we aim to empower manufacturers with the knowledge required to make informed decisions about the right plastic additives to meet their specific manufacturing needs and to optimize their product offerings in a competitive market.

Understanding the Types of Plastic Additives Available in the Market

When selecting plastic additives for manufacturing, it's essential to understand the various types available in the market and their respective applications. Plastic additives can be broadly categorized into functional additives, such as antioxidants and UV stabilizers, and processing aids, such as plasticizers and lubricants. According to a report by MarketsandMarkets, the global market for plastic additives was valued at approximately $50 billion in 2022, with a projected growth at a CAGR of 5.4% through 2027. This significant growth underscores the increasing demand for specialized additives that enhance the performance and durability of plastics across various applications.

Functional additives play a critical role in improving the longevity and stability of plastic products. For instance, UV stabilizers protect plastics from degradation caused by exposure to sunlight, which is particularly relevant in outdoor applications. Meanwhile, antioxidants help to prevent oxidative degradation, offering better resistance to heat and mechanical stress. On the other hand, processing aids, such as plasticizers, improve the flexibility and processability of plastics, making them essential in the production of flexible materials. According to a study by Allied Market Research, the plasticizer segment alone accounted for about 27% of the total plastic additives market in 2021, illustrating its pivotal role in enhancing product characteristics.

Understanding these types of additives and their applications can significantly impact the performance and compatibility of your plastic products, ensuring they meet industry standards and consumer expectations. As manufacturers increasingly seek to optimize their processes and product quality, choosing the right additives becomes an essential part of the manufacturing strategy, influencing everything from production efficiency to end-user satisfaction.

Identifying Your Specific Manufacturing Requirements and Applications

When choosing the right plastic additives for your manufacturing needs, it is vital to first identify your specific manufacturing requirements and applications. Begin by assessing the type of plastic you'll be working with, as different polymers may demand distinct additives to achieve desired properties such as flexibility, durability, and UV resistance. Understanding the environmental conditions the final product will face is also crucial, as this can influence the selection of stabilizers and antioxidants that protect the material from degradation over time.

Next, consider the intended uses of the plastic products. Will they be subjected to high temperatures, exposure to chemicals, or mechanical stress? Tailoring your choice of additives to these conditions will ensure optimal performance. For instance, if products are to be used in a food-related application, it is essential to choose additives that comply with relevant safety regulations. Consulting with material experts and conducting thorough testing can further refine your choices, ultimately leading to enhanced product quality and performance tailored specifically to your manufacturing needs.

Evaluating the Compatibility of Additives with Different Plastics

When selecting plastic additives for manufacturing, assessing the compatibility of these additives with various types of plastics is crucial for achieving the desired performance and durability of the final product. Different plastics possess distinct chemical structures and properties, which can significantly influence how they interact with specific additives. For example, additives such as stabilizers, plasticizers, and fillers can enhance certain characteristics but may also lead to adverse reactions if not compatible. Understanding the molecular composition of both the plastic and the additive can help in making informed choices that enhance product quality.

To effectively evaluate compatibility, manufacturers should consider conducting preliminary tests that focus on compatibility under real processing conditions. This could include examining changes in physical properties, such as tensile strength, flexibility, and thermal stability, after mixing the additive with the plastic. Additionally, it’s important to assess the long-term stability of the products, as some additives may degrade or react over time, potentially compromising the integrity of the material. Monitoring how additives influence the processing behavior, such as melt flow rate and temperature stability, is also vital. Proper evaluation ensures that the selected additives will not only improve performance but also maintain the intended functionality of the plastic in various applications.

Choosing the Right Plastic Additives for Your Manufacturing Needs

This chart illustrates the compatibility of various plastic additives with different types of plastics including Polypropylene (PP), Polyethylene (PE), and Polyvinyl Chloride (PVC). The y-axis represents the compatibility level on a scale from 1 to 10, while the x-axis shows different types of additives.

Analyzing the Impact of Additives on Product Performance and Durability

The selection of plastic additives plays a crucial role in enhancing the performance and durability of manufactured products. Various additives, such as plasticizers, stabilizers, and fillers, can significantly influence the mechanical properties and longevity of plastics. For instance, according to a report by Grand View Research, the global plastic additives market was valued at approximately $54 billion in 2020, and it is projected to expand at a compound annual growth rate (CAGR) of 5.6% from 2021 to 2028. This growth is largely driven by increasing demand for enhanced performance in applications ranging from automotive to consumer goods, showcasing the critical need for effective additive selection.

Additives serve specific functions that address the challenges faced in production and the end-use of plastic products. For example, UV stabilizers can prevent degradation from sunlight exposure, thus significantly extending the lifespan of outdoor products. A study published in the Journal of Applied Polymer Science indicates that incorporating certain UV stabilizers can increase the longevity of polyolefin materials by up to 40%, making them a wise investment for manufacturers who prioritize durability. Moreover, the choice of additives can also affect processing behavior and product quality, underscoring the importance of a thorough evaluation of each additive's impact on the overall performance metrics of the final products. Hence, understanding the interaction between selected additives and the base polymers is essential for achieving optimal outcomes in manufacturing.

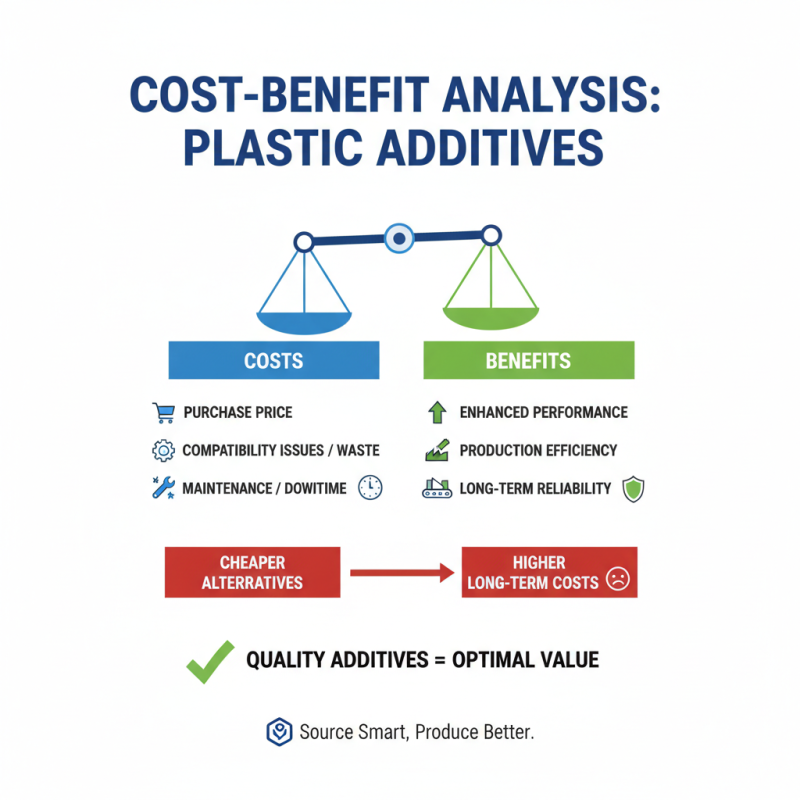

Cost Considerations and Sourcing Quality Plastic Additives for Production

When it comes to sourcing quality plastic additives for production, cost considerations play a vital role in decision-making. Manufacturers must evaluate the total cost of ownership, which includes not only the purchase price of the additives but also their compatibility with existing processes, potential waste, and the impact on overall production efficiency. Opting for cheaper alternatives might seem appealing at first, but the long-term implications, such as performance issues or increased maintenance, can lead to higher costs down the road. Thus, a comprehensive cost-benefit analysis is essential in identifying the right additives that meet both budgetary constraints and performance requirements.

Moreover, sourcing quality plastic additives requires a systematic approach to vendor selection. Ensuring that suppliers meet stringent quality standards is indispensable for maintaining consistency in production. Companies should conduct thorough research on their suppliers’ manufacturing processes, certification statuses, and customer feedback. Building strong relationships with reliable suppliers can lead to better pricing, improved service, and the ability to negotiate terms that align with production needs. Ultimately, prioritizing both cost and quality in additive selection will lead to enhanced product performance and profitability.

Related Posts

-

How to Recycle Plastic Effectively: A Comprehensive Guide to Plastic Waste Management

-

2025 Top Trends in Plastic Compound Innovations and Applications

-

The Hidden Role of Plastic Additives in Sustainable Material Innovation

-

Exploring the Masterbatch Market: Trends, Innovations, and Future Growth Projections

-

Unlocking the Secrets of Plastic Filler Compounds: The Ultimate Guide to Their Applications and Benefits

-

2025 Top 10 Anti Retardant Products for Enhanced Safety and Performance