Blog

Ultimate Tips for Choosing the Right PP Masterbatch for Your Projects

When embarking on a project that requires the use of polypropylene (PP) materials, the choice of PP masterbatch becomes a critical factor in achieving optimal results. This selection process not only influences the final appearance and functionality of the product but also plays a significant role in production efficiency and cost-effectiveness. Therefore, understanding what to look for in a PP masterbatch is essential for designers, engineers, and manufacturers alike.

Numerous factors can impact the performance of PP masterbatch, including its composition, colorant types, and carrier resin compatibility. Moreover, it is important to consider the specific requirements of your application, such as processing temperatures and environmental conditions. With an array of options available in the market, having the right guidelines can help streamline the selection process, ensuring that your projects meet both technical and aesthetic demands.

In the following sections, we will delve into the ultimate tips for choosing the right PP masterbatch, equipping you with the knowledge needed to make informed decisions that will enhance the quality and durability of your products. By considering these factors, you can optimize your projects for success while minimizing potential challenges associated with poor masterbatch selection.

Key Characteristics of High-Quality PP Masterbatch

When selecting the right polypropylene (PP) masterbatch for your projects, understanding the key characteristics of high-quality options is essential. One of the most critical attributes is the dispersion quality of the pigments used in the masterbatch. A high-quality PP masterbatch ensures uniform dispersion, which is crucial for achieving consistent color and performance in the final plastic products. According to a recent industry report from MarketsandMarkets, the global masterbatch market is projected to reach $13.09 billion by 2023, indicating strong demand for products that emphasize superior pigment dispersion.

Another important characteristic to consider is the thermal stability of the PP masterbatch. High-quality formulations should maintain their properties when subjected to the processing conditions typical in the plastic manufacturing industry, such as high temperatures and shear rates. Research conducted by Grand View Research highlights that masterbatch with enhanced thermal stability not only prolongs the lifespan of the machinery involved in production but also prevents degradation of the final product. The data indicates that a masterbatch with excellent thermal resilience can outperform less stable alternatives, ultimately delivering better results for manufacturers looking to optimize their processes.

Finally, the compatibility of the PP masterbatch with other polymers is a vital consideration. A versatile masterbatch allows for seamless integration with various plastic resins, enhancing the potential applications across different industries. The European Plastics Converters (EuPC) reports that such compatibility can significantly improve the performance attributes of the final product, promoting efficiency and cost-effectiveness in manufacturing. As the industry continues to evolve, focusing on these key characteristics will ensure you select a PP masterbatch that meets the demands of modern projects.

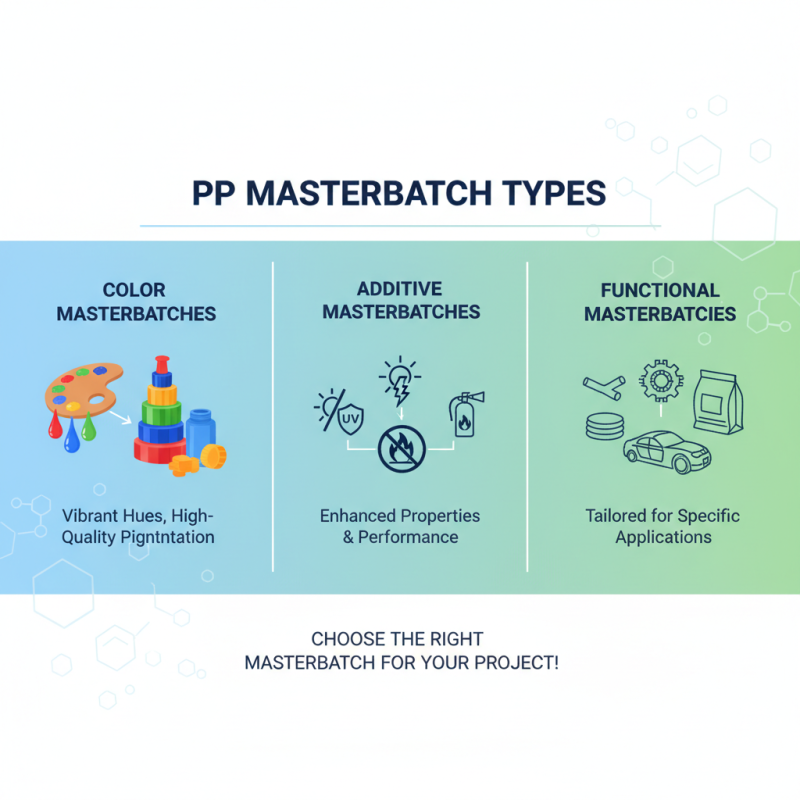

Understanding Different Types of PP Masterbatch Available

When selecting the appropriate polypropylene (PP) masterbatch for your projects, understanding the various types available is crucial. PP masterbatches can be categorized based on their function—color masterbatches, additive masterbatches, and functional masterbatches. Color masterbatches are designed to impart vibrant hues to the final product, while additive masterbatches include UV stabilizers, antistatic agents, and flame retardants that enhance the material's properties and performance. According to industry reports, the global demand for color masterbatches is projected to grow by approximately 5.2% annually, highlighting the increasing importance of high-quality pigmentation in plastic products.

Furthermore, functional masterbatches serve specific roles such as improving the strength or elasticity of polypropylene. These masterbatches are especially valuable in applications requiring enhanced durability or performance. A survey by a leading market research firm revealed that functional additives in masterbatches are expected to see a compound annual growth rate (CAGR) of 6.1% through 2026, driven by advancements in plastic applications across various industries, including automotive and packaging. Understanding the differences between these types will help you make informed choices that align with the specific requirements of your project while also optimizing the performance and aesthetic appeal of your final products.

Factors to Consider When Selecting PP Masterbatch for Your Application

When selecting the right polypropylene (PP) masterbatch for your project, several key factors must be considered to ensure optimal performance and compatibility with your specific application. One of the primary considerations is the intended use of the final product. For instance, if your application demands high durability, such as in automotive parts, choosing a PP masterbatch with enhanced impact resistance is crucial. According to market research by Smithers Pira, the demand for specialty additives, including masterbatches, is expected to grow by 4.8% annually through 2025, showcasing the increasing importance of tailored solutions in various industries.

Another important factor is the color and compatibility of the masterbatch with your base polymer. The right color match not only enhances aesthetics but also assures the stability of the color during processing and the lifespan of the product. Studies have indicated that variations in pigmentation can affect the thermal stability of the polymer matrix. Selecting a PP masterbatch that undergoes rigorous testing for heat resistance and UV stability can significantly prolong the lifespan of products used in outdoor applications, as highlighted in a recent report from Transparency Market Research which indicated that 60% of users experienced improved durability when using properly tested masterbatches.

Additionally, processing conditions, such as temperature and shear rate, must be taken into account. Masterbatches are formulated to perform under specific processing scenarios, and mismatches can lead to separation and poor dispersion. Research indicates that dispersive mixing properties are vital, as homogeneous mixing of the masterbatch with the base material can enhance mechanical properties and end-product performance. Understanding the parameters of your application and aligning them with the characteristics of the masterbatch will lead to better outcomes in product performance and compliance with industry standards.

Evaluating Performance and Compatibility of PP Masterbatch

When selecting the right polypropylene (PP) masterbatch for your projects, evaluating performance and compatibility is crucial. Masterbatches, which are concentrated mixtures of additives with a carrier resin, can significantly influence the physical and mechanical properties of the final product. According to a recent industry report, the market for PP masterbatch is projected to grow at a CAGR of over 5% from 2021 to 2027, highlighting the increasing demand for high-performance materials across various applications, including packaging, automotive, and consumer goods.

To ensure optimal performance, it is essential to assess the masterbatch's compatibility with the base polymer. This involves analyzing the melt flow rate, thermal stability, and color dispersion characteristics. A study from industry experts found that incorporating a well-dispersed masterbatch can improve the tensile strength of PP by up to 20%. Furthermore, its compatibility affects not just the mechanical properties but also the processing behavior during extrusion and molding, which can lead to significant cost savings and efficiency improvements in production.

Additionally, understanding the specific requirements of your application is vital. For instance, projects requiring enhanced UV resistance or antibacterial properties necessitate specialized masterbatches. The right choice can reduce degradation and prolong the lifespan of the end product. As per recent findings, projects utilizing advanced masterbatches can see a performance enhancement of over 15%, thus reinforcing the importance of thorough evaluation of both performance metrics and compatibility with the desired application.

Cost vs. Quality: Making Informed Decisions for PP Masterbatch

When selecting the right polypropylene (PP) masterbatch for your projects, the balance between cost and quality is paramount. Many manufacturers face the dilemma of opting for cheaper materials to cut costs, but this can lead to significant drawbacks in the long run. Inferior masterbatches may compromise the performance and durability of the end products, resulting in increased waste, higher rework rates, and ultimately, customer dissatisfaction. Thus, understanding the cost implications versus the quality benefits is crucial for making informed decisions.

Investing in high-quality PP masterbatch can initially seem more expensive, but the long-term advantages often outweigh the initial costs. High-quality masterbatches provide better dispersion, enhanced color vibrancy, and superior mechanical properties, ensuring that the final products meet industry standards and customer expectations. Moreover, they tend to have a more consistent performance, reducing the risk of production delays and additional expenses. Consider the specific needs of your project, and focus on the total cost of ownership rather than just the purchase price. This approach will lead to superior outcomes, making your investment in quality masterbatch a strategic choice rather than a mere expense.

Related Posts

-

2025 Top Trends in Plastic Masterbatch and Its Impact on the Industry

-

How to Choose Bioplastic Packaging: A Complete Guide for Eco-Friendly Choices

-

Exploring the Science Behind Color on Plastic: How Pigments Transform Materials

-

Exploring the Future of Sustainability with Bio Plastics and Their Impact on Our Environment

-

Exploring the 2025 Top Types of Plastics in Our Ever-Changing Plastic World

-

Top 10 Benefits of Using Plastic Compounds in Modern Manufacturing