Blog

Top Compounds for Plastic in 2025 What You Need to Know

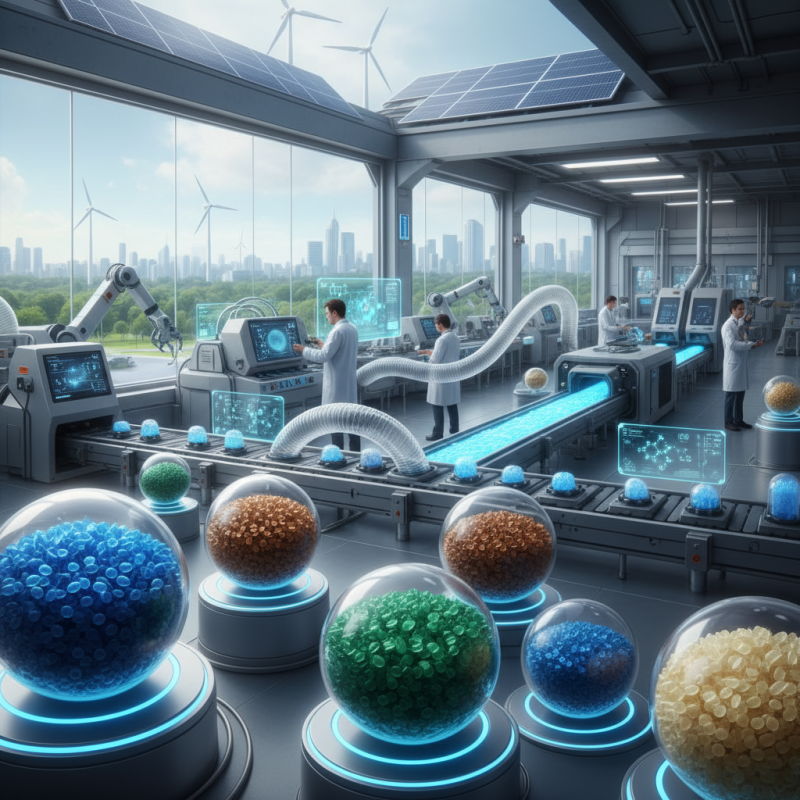

As we look towards the future of materials science in 2025, the significance of innovative compounds for plastic is increasingly evident. These compounds are set to redefine the landscape of plastics, addressing both sustainability concerns and performance enhancements. With the growing demand for environmentally-friendly solutions, researchers and manufacturers are focusing on developing compounds that not only fulfill traditional roles but also minimize environmental impact, thereby contributing to a circular economy.

In this context, the exploration of new compound for plastic becomes essential. These advanced materials promise to deliver improved physical properties, increased durability, and greater versatility in applications across various industries. From automotive to consumer goods, the evolution of plastic compounds is critical in meeting the coming challenges of resource management and regulation. By delving into the top compounds anticipated to make waves in the plastics sector by 2025, we can better understand the trends that will shape the market and the innovations that will drive future developments.

Key Trends in Plastic Materials for 2025

The landscape of plastic materials is poised for significant evolution in 2025, driven by sustainability and innovative compound development. One of the key trends is the increasing incorporation of bio-based plastics, derived from renewable resources. These materials offer a more environmentally friendly alternative to traditional petroleum-based plastics, appealing to industries looking to reduce their carbon footprint. Additionally, advancements in bioplastics are improving their mechanical properties, making them suitable for a broader range of applications, from packaging to automotive components.

Another critical trend is the focus on recyclability and circular economy principles. Manufacturers are intensifying efforts to design plastic materials that can be efficiently recycled, thus minimizing waste and conserving resources. Closed-loop systems are gaining traction, where used plastics are collected and reprocessed into new products. Furthermore, innovations in chemical recycling technologies are enabling the transformation of previously non-recyclable plastics back into usable materials, contributing to a more sustainable plastic life cycle. As these trends continue to develop, the plastic industry is likely to witness a shift towards more responsible material sourcing and production practices, aligning with global sustainability goals.

Emerging Compounds Revolutionizing Plastic Production

The landscape of plastic production is undergoing a significant transformation, driven by the emergence of innovative compounds that promise to enhance functionality and sustainability. In 2025, these new materials, developed through advanced chemical processes, are set to revolutionize the way plastics are created, used, and recycled. Among these advancements are bio-based polymers derived from renewable resources, which not only reduce dependency on fossil fuels but also exhibit comparable durability and flexibility to conventional plastics. These compounds are designed to meet the growing demand for environmentally friendly alternatives, making a substantial impact on both consumer choices and regulatory compliance.

Another exciting area of development is the incorporation of nanomaterials into plastic production. These nanoscale additives improve the mechanical properties, thermal stability, and barrier functions of plastics, leading to enhanced performance in various applications. For instance, integrating nanoclays or carbon nanotubes can significantly increase the strength of polyolefins while reducing their weight, presenting opportunities for industries ranging from automotive to aerospace. As these emerging compounds gain traction, they pave the way for a new generation of plastics that offer improved lifecycle characteristics, ultimately fostering a circular economy that emphasizes reuse and recycling in an environmentally responsible manner.

Environmental Impact of New Plastic Compounds

The development of new plastic compounds in 2025 is poised to make a significant impact on environmental sustainability. With increased awareness of plastic pollution and its consequences, research is focusing on creating materials that minimize ecological footprints. Many of the top compounds emerging in the industry are designed to be biodegradable or derived from renewable resources, making them more eco-friendly alternatives to traditional plastics. These innovations aim to tackle the pressing issue of plastic waste by enabling faster breakdown in natural environments, thereby reducing the burden on landfills and oceans.

Furthermore, the environmental impact of these new plastic compounds extends beyond their biodegradability. Many are formulated to utilize less energy during production and to emit fewer harmful gases than conventional plastics. This not only alleviates the negative effects associated with fossil fuel extraction and processing but also contributes to a lower carbon footprint throughout their lifecycle. As these materials enter the market, they are expected to offer manufacturers a viable pathway to adhere to stricter regulations and consumer demands for sustainability, ultimately fostering a cleaner and healthier planet.

Applications of Innovative Plastic Materials in Various Industries

Innovative plastic materials are reshaping various industries in unprecedented ways, driven by the need for sustainability and enhanced performance. In the automotive sector, advanced composites and biodegradable plastics are being developed to reduce vehicle weight and improve fuel efficiency while minimizing environmental impact. These materials not only meet stringent safety standards but also contribute to enhanced recyclability, making them an attractive choice for manufacturers looking to adopt greener practices.

In the packaging industry, the shift towards smart plastics is revolutionizing how products are contained and preserved. Utilizing materials with embedded sensors, companies can create packaging that monitors freshness, temperature, and even tampering. These innovations not only extend shelf life and reduce food waste but also provide consumers with valuable information about the products they purchase. The integration of innovative plastic solutions in healthcare is also noteworthy; biocompatible polymers are being used in medical devices and prosthetics, offering safer and more effective alternatives while catering to specific patient needs. This ongoing transformation underscores the pivotal role of innovative plastic materials across various sectors, shaping a more sustainable future.

Top Compounds for Plastic in 2025

| Compound | Properties | Applications | Projected Growth (%) |

|---|---|---|---|

| Polyamide (Nylon) | High strength and durability, chemical resistance | Automotive parts, textiles, consumer goods | 6.5% |

| Polycarbonate | High impact resistance, optical clarity | Safety goggles, automotive headlamps, electronics | 5.8% |

| ABS (Acrylonitrile Butadiene Styrene) | Good balance of strength and toughness | Consumer electronics, toys, automotive interiors | 4.2% |

| PLA (Polylactic Acid) | Biodegradable, low environmental impact | Packaging, disposable cutlery, 3D printing | 8.0% |

| PVC (Polyvinyl Chloride) | Versatile, weather-resistant, and durable | Construction, electrical cable insulation, medical devices | 3.5% |

Future Challenges and Opportunities in Plastic Manufacturing

As the plastic manufacturing industry approaches 2025, it faces significant challenges and opportunities that could reshape its future. One of the foremost challenges is the growing pressure to adopt sustainable practices amid rising environmental concerns. According to a report by Smithers, the global demand for biodegradable plastics is expected to reach 2.9 million metric tons by 2025, highlighting a shift towards eco-friendly alternatives. Manufacturers must not only innovate their materials but also rethink their production processes to minimize waste and carbon emissions.

Opportunities also emerge from advancements in technology and material science. The rise of 3D printing and smart plastics presents avenues for manufacturers to create lightweight, high-performance products more efficiently. The International Plastics Association predicts that by 2025, the integration of AI and machine learning in manufacturing processes could enhance productivity by up to 20%. Companies that invest in these technologies are likely to gain a competitive edge in the evolving marketplace.

Tips: To navigate these challenges, manufacturers should invest in research and development for sustainable materials. Collaborating with universities and research institutions can lead to innovative solutions that meet consumer demands for sustainability. Additionally, staying informed about regulatory changes and market trends is crucial for adapting strategies effectively. Leveraging emerging technologies can also optimize production and reduce waste, making processes more efficient while aligning with environmental goals.

Related Posts

-

Exploring the Future: Innovations in Plastic Compound Technology for Sustainable Manufacturing

-

2025 Top Trends in Plastic Compound Innovations and Applications

-

How to Recycle Plastic Effectively: A Comprehensive Guide to Plastic Waste Management

-

Exploring the Latest Innovations in Anti Retardant Materials for Enhanced Fire Safety

-

Exploring the 2025 Top Types of Plastics in Our Ever-Changing Plastic World

-

Exploring the Masterbatch Market: Trends, Innovations, and Future Growth Projections